Against the backdrop of rapid development in the current technology industry, high bandwidth memory (HBM), as a key technology for improving computing performance, has seen a sustained increase in market demand, resulting in a complete shortage of production capacity bookings. In order to meet the constantly expanding market demand, Micron Technology, a leading global semiconductor manufacturer, announced a capacity expansion plan and introduced advanced smart logistics systems to optimize production processes, improve efficiency, and ensure supply chain stability and flexibility. Recently, the two parties officially signed a milestone project order, marking a new chapter in the deep cooperation of AstraZeneca in the field of intelligent logistics in the semiconductor industry! The deep cooperation between Aisdak and Micron aims to jointly develop an innovative high-end HBM wafer storage solution in the industry. Through i-Stock's self-developed software system, nitrogen storage technology is deeply integrated with automated handling systems (AGV and OHT) to achieve seamless integration with OHT transportation, AGV scheduling, and AMHS systems, maintaining the storage of wafers in a standard nitrogen environment. Accurate control of nitrogen concentration is required to avoid damage to the wafer surface, while ensuring that environmental parameters such as temperature and humidity during storage comply with strict standards. This not only marks a milestone in semiconductor storage technology, but also opens up new possibilities for the development of the semiconductor industry, indicating that in the future, semiconductor smart logistics technology will move towards a more efficient, intelligent, and secure direction.

1、HBM

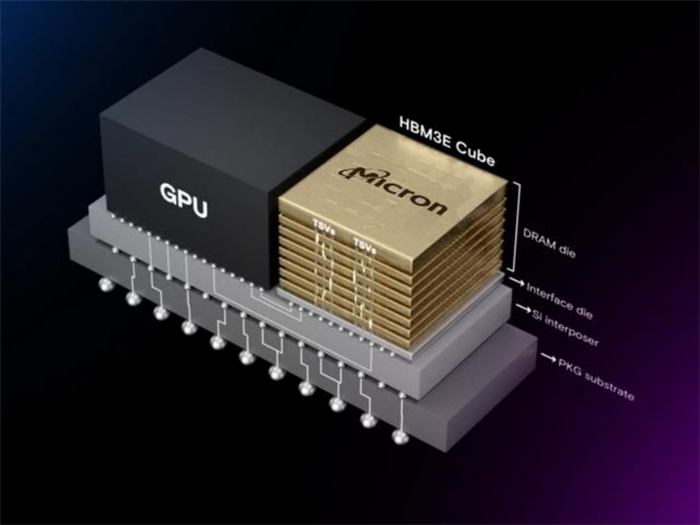

HBM "is a new type of CPU/GPU memory chip, abbreviated as High Bandwidth Memory. HBM has become a standard equipment for AI servers, meeting the massive computing power demand. The rise of AI big models has generated a massive demand for computing power, with higher requirements for chip memory capacity and transmission bandwidth. HBM "is a high-performance DRAM based on 3D stack technology initiated by AMD and SK Hynix, suitable for applications with high memory bandwidth requirements, such as graphics processors, network switching and forwarding devices (such as routers, switches), etc.

2、HBM's expansion and technological upgrading trend

Micron's largest HBM memory production base is currently located in Taichung City, Taiwan, and it is increasing production capacity at its Taichung factory. Sources have revealed that Micron is currently expanding its research and production facilities related to HBM at its headquarters in Boise, Idaho, USA, including technology validation and mass production lines. In addition, Micron is also considering building HBM production capacity in Malaysia for the first time. Micron currently has chip testing and assembly facilities under construction in Malaysia, and potential capacity building is expected to focus on the backend process. According to data from Morgan Stanley, AI computing chip giant Nvidia is also the largest buyer of HBM memory, purchasing approximately 48% of the global HBM production capacity this year. Micron announced in February this year that its 8Hi 24GB HBM3E memory has entered the mass production stage and is supplying Nvidia H200 chips.

3、AI drives performance growth

Sanjay Mehrotra, CEO of Micron, stated that strong demand for artificial intelligence and excellent execution capabilities enabled Micron to achieve a 17% quarterly revenue growth in the third quarter, surpassing the financial forecast range. Mehrotra also stated that Micron's high bandwidth memory (HBM) and other high profit products continue to rise in market share, and data center SSD revenue has reached a historic high, demonstrating its AI product portfolio strength in the DRAM and NAND fields. The strong demand for AI driven data center products has led to tight production capacity in advanced processes. Therefore, despite the recent stable demand for personal computers (PCs) and smartphones, Micron expects prices to continue to rise during the period of January December 2024. Looking ahead to 2025, the demand for AI PCs, AI smartphones, and the continuous growth of data center AI have created a favorable environment, giving Micron confidence to achieve significant revenue records in the 2025 fiscal year and significantly improve profitability driven by the continued shift towards higher profit products in the product portfolio.

Current situation of local industrial chain development

Chinese enterprises are actively catching up with HBM technology, and packaging manufacturers already have the technology to support HBM production. Material, packaging and testing, and equipment manufacturers are also actively carrying out HBM related cooperation. The coordinated development of local industrial chains is the key to enhancing the competitiveness of HBM in China. The integration and optimization of the entire industry chain, from raw materials to packaging and testing, is crucial for improving the overall level of China's HBM industry. As a supplier of intelligent logistics solutions for Micron, AstraZeneca has planned and implemented more than 20 semiconductor intelligent logistics overall solutions for Micron Technology in various global factories, jointly promoting the transformation of Micron Technology's global production base into intelligent factories. The intelligent logistics solution of high-end HBM wafer nitrogen filling storage and automatic handling by Aisdak Intelligent Technology not only brings significant production efficiency improvement and cost savings to Micron's customers, but also reflects the core values of technology in modern manufacturing industry - innovation, efficiency, environmental protection, and sustainability. With the continuous advancement of technology, we look forward to the deep cooperation between AstraZeneca and global leading companies such as Micron, continuing to lead the industry in new directions and bringing new breakthroughs and innovations to the industry. At the same time, it also injects new momentum and opportunities for the common development of both sides.

Aisdak always adheres to customer needs as the core, driven by intelligent equipment and precision technology, industrial software connects data flow, data+AI algorithm empowers smart warehousing in the electronics and semiconductor industries, focuses on product quality, and serves with dedication. Aisdak helps enterprises solve practical problems encountered in the scientific, standardized, digital, automated, and intelligent upgrading of intelligent warehousing, and provides customized services for intelligent warehousing equipment. In the future, AstraZeneca will continue to leverage its advantages in technical talent and resources to contribute to the transformation and upgrading of the manufacturing industry. In this process, AstraZeneca will assist more HBM manufacturing enterprises, work together to promote China's manufacturing industry to the top of the global value chain.